USES

CHEM-DOWEL 2 is a non-abrasive structural epoxy adhesive designed for applications into horizontal holes drilled in concrete for setting of dowel rods, re-bars, etc., in high way or airport runway slabs. The moderate setting adhesive may be mixed and applied by hand, machine, or caulking gun into the drilled holes.

CHEM-DOWEL 2 is a structural adhesive also applicable for bonding of:

- Concrete to concrete.

- Glass to wood.

- Aluminum-to-Aluminum and any other combination of similar or dissimilar construction materials.

The product CHEM-DOWEL 2 is used in the fields of:

- Roads and bridges constructions.

- Airports and Airbase constructions.

- Maintenance facilities of highway and bridges.

- Car parking, ramps and driveways.

- Airport, Airbase runways, aprons, etc.

TECHNICAL

Technical Data for Unmixed Parts

| Property @ 25°C (77°F) |

Resin Part A |

Hardener Part B |

Test Method |

| Solids |

100 % |

100 % |

–

|

| Color |

White |

Black |

–

|

| Density, Lb/Gal (Kg/L) |

14.9 (1.8) |

14.2 (1.71) |

ASTM D1475 |

| Consistency |

Paste |

Paste |

–

|

| Mixing Ratio A : B |

1 : 1 By Volume |

–

|

| Shelf Life |

2 years |

2 years |

–

|

Technical Data for Mixed Parts

| Property (Mixed A & B) |

Value @ 25°C (77°C) |

Test Method |

| Mixed Density, Lb/Gal (kg/L) |

15 (1.8) |

ASTM D1475 |

| Viscosity |

Thixotropic Paste |

–

|

| Mixed Color |

Grey |

–

|

| Shore Hardness @ 7 Days, D |

80 |

ASTM D2240 |

| Gel Time @ 5 mils, hour |

6 – 8 |

ASTM D2471 |

| Pot Life @ 3 OZ (90 Milliliter), minute |

30 |

–

|

| Tensile Strength, Psi (MPa) |

4400 (30) |

D-638 |

| Compressive Strength @ 3 Days, Psi (MPa) |

10140 (69) |

D-695 |

| Bond Strength @ 3 Days, Psi (MPa) |

530 (3.6) |

C321 |

| Bond Strength @ 3 Days, Psi (MPa) |

2060 (14) |

C-882 |

| Flexural Strength @ 3 Days, Psi (MPa) |

5150 (35) |

C-348 |

| Tensile Strength @ 3 Days, Psi (MPa) |

4400 (30) |

D-638 |

| Water Absorption 24 hrs, % |

0.2 |

ASTM D570 |

| Elongation (Average), % |

5 |

ASTM D638 |

| Rod Pull (Ultimate), Lb (Kg) |

12000 (5443) |

25×225 mm |

| Final Cure, day |

3 |

–

|

APPLICATION

Limitations:

- Applications at ambient temperatures below 4°C is not recommended.

Pre-treatment of Substrate:

Concrete Surfaces:

The surface or holes must be clean, dry, free from grease or oil, etc. Laitance and loose particles must be removed by either sandblasting or mechanical grinding. Holes must be cleaned using dry and oil free compressed air.

Steel Surfaces:

All steel surfaces to be bonded with CHEM-DOWEL 2 must be clean, dry, free from rust, oil, grease, etc. Shot blasting to Swedish Standard SA 2 ½ is preferable to achieve a white metal finish prior to application.

Holes for Setting Dowels:

Holes Dimensions: the annular space between anchor rod, dowel, rebar, etc., and hole should be as small as possible 3-5mm yet still provide ease of placement.

Depth of Embedment Guidelines:

- When substrate has compressive strength of 21 N/mm² and greater or the anchor bolts are threaded, the minimum depth is 10 times the bolt diameter.

- For grouting smooth bolts or into substrates with less than 21 N/mm², the minimum depth of embedment is at least 15 times the bolt diameter

Drilling:

- Dry Drilling: Vacuum or blow out the dust from hole using oil free compressed air or blow pump

- Wet Drilling: Wash out hole with clean water to remove residue of drilling slurry. Remove free standing water. It is preferable to allow the hole to complete dry.

- Bolts, dowels, rebars must be clean de-rust, dry and de-grease.

Mixing of CHEM-DOWEL 2: stir each component separately. Mix one part A and one part B by volume into a clean mixing container. Mix the epoxy with a slow speed electric drill with a mixing paddle attachment. Carefully scrape the sides and bottom of the pail during mixing. Blend for 3 minutes.

Note: Large batches of epoxy will cure much faster than small batches. Mixed epoxy will cure much faster in hot weather than in cold weather.

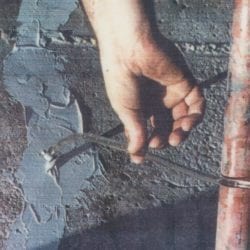

Application: application can be made by mechanical, pneumatic dosage equipment, caulking guns or by hand. Force the mixture into drilled hole, then insert the steel bar with a twisting motion to ensure intimate contact and a good bond without air entrapment

Lightly tap the anchor, dowel to ensure complete embedment. Wipe off any excess material from the surface and finish to a neat smooth surface.

Bonding of any similar/dissimilar material: ensure both surfaces to bond is clean and free of dust, oil, grease, etc. Roughen up the surfaces for good mechanical keying. Apply in thin layer CHEM-DOWEL 2 on both surfaces. Pull them together and hold into position undisturbed for 6 – 8 hrs.

Curing: initial setting is minimum 8 hours. Full cure in 3 days.

Cleaning: remove uncured CHEM-DOWEL 2 from tools and equipment with a suitable solvent such as Xylene or Toluene immediately after use. Cured material may only be removed mechanically.

STORAGE

Store in a dry area between 10ºC and 25ºC. Protect from direct sunlight. Shelf life is minimum two years in original un opened container.

SAFETY

After full curing the product is physiologically harmless. Keep the resin and hardener away from the eyes, mouth and skin. Do not inhale vapors. Uncured mixture can cause irritation of the skin. The best precaution is to wear safety protective gloves, overall, mask and goggles while working. Skin contamination should be immediately cleaned with soap and plenty of water. The use of solvents should be avoided. If resin or hardener splashes into the eyes, wash immediately with running water. A Doctor must be visited in all cases.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM24319.