ADVANTAGES

- Ready to use and cold applied.

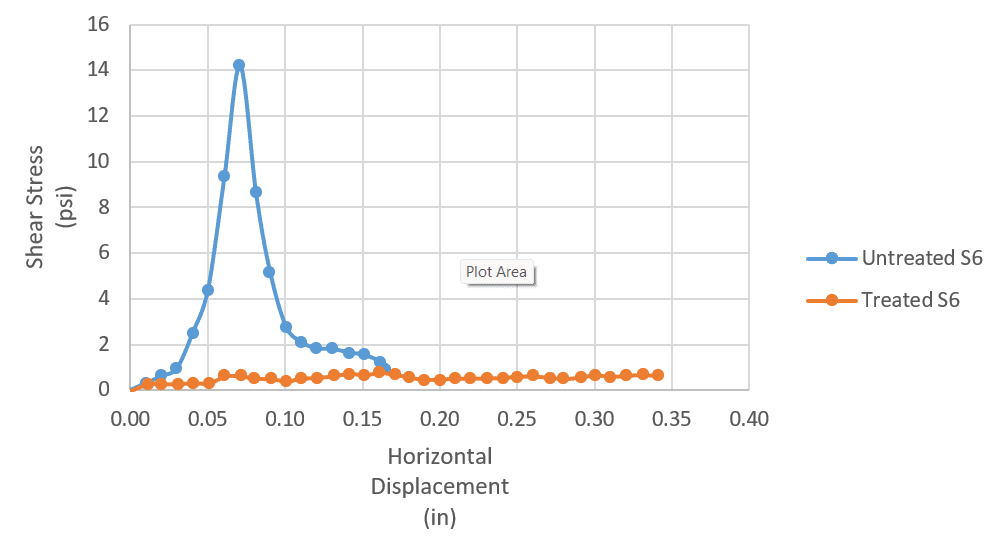

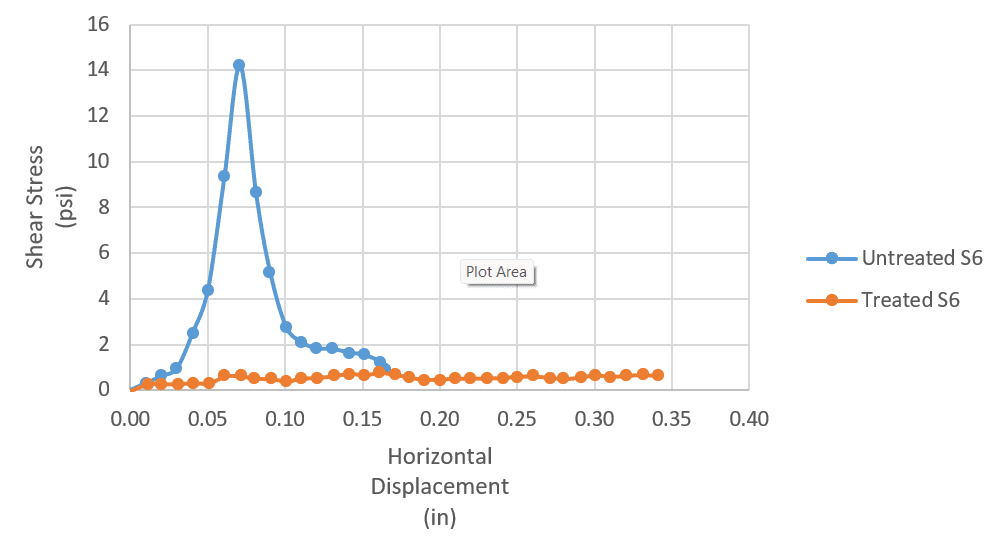

- Reduces ice adhesion (shear testing) by more than 90% (see Fig. 2) and hence reduces the consumption of deicing chemicals by > 60%.

Fig. 1: Ice Adhesion Test Results comparing control (blue) & ASP-treated (red) using IOWA-DOT HMA pavement mix design using Modified Direct Shear Apparatus (Geocomp SheraTrac-II)

- Low viscosity that allows for deep penetration through voids and capillaries.

- Provides asphalt surface with Hydrophobicity characteristics: Excellent water-repelling properties that help reduces water, jet fuel, and oil from penetrating asphalt pavement surfaces: ASP increases water contact angle for asphalt surfaces.

- Increases durability and sustainability of asphalt pavement by reducing asphalt rutting and deflection in both topical and intermixed applications based on both IOWA DOT standard and high traffic pavement mixes design.

- Increases stability of HMA pavement by 327% using topical application.

- Suitable for all climates.

- Seals cracks up to 1/8th of an inch (3 mm) without the need for routing or crack sealing.

- Enhances the bonding properties between pavement elements thus eliminates surface deterioration, chipping, and cracks formation.

- Reduces damages caused by repeated freezing and thawing cycles.

- Protects against chemical attacks caused by chlorine ions from de-icing salts, acids, and caustics.

- Enhances the adhesion property of road markers.

- Reduces vegetation growth.

- Dry fast and thermally stable.

- UV stable.

- Restriping and marking in short time after surface is dry (4 to 6 hours)

- Reduce the consumption of deicing materials by greater than 50%.

USES

ASP is used for protection of all kinds of asphalt pavements such as:

TECHNICAL

Physical Properties:

| Property |

Value @ 25°C (77°C) |

Test Method |

| Specific Gravity |

0.90 – 0.92 |

ASTM D1475 |

| Viscosity, cPs |

90 – 120 |

Brookfield |

| Solid Content, % |

55 – 57 |

–

|

| Color |

Black |

–

|

| Odor |

Asphaltic |

–

|

| Fumes |

None |

– |

Product Performance: ASP is tested according to the following test standards:

- AASHTO T 3224 – Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures

- AASHTO T 166 – Standard Method of Test for Bulk Specific Gravity (Gmb) of Compacted Asphalt Mixtures Using Saturated Surface-Dry Specimens

- AASHTO T 245 – Standard Method of Test for Resistance to Plastic Flow of Asphalt Mixtures Using Marshall Apparatus

- ASTM F 606 – Static Slip Resistance Test

- ASTM E 303 – Surface Frictional Properties

- California Test 366 – Stabilometer Value

APPLICATION

Preparation: surface must be clean and sound prior to applying the product. Compressed air or heavy-duty mechanical brushing can be used to remove dust and loose particles from the surface.

Application: ASP is a ready to use material. It can be applied to asphalt surfaces in one single coat only by means of spraying, sweeping or brushing. For large-scale applications, such as asphalt highways, it is recommended to spray the product using a heavy-duty commercial sprayer.

Coverage: it is recommended to apply ASP at an average rate of 100 to 125 ft2 / Gal (2.45 to 3.1 m2/liter) in one application only.

Crack Repair: for cracks as wide as 1/8 in (3 mm) width, mix 1 volume of ASP with 3 volumes of fine sand and pour into opened and pre-cleaned crack.

Pot-Holes Repairs: to repair small pot-holes, heat the pavement and break it around the pothole. Spray the bottom of the pothole with ASP. Mix the broken pavement with ASP, and compact it back into the pothole area. For better performance, spray the compacted pavement with at an average rate of 100 to 125 ft2/Gal (2.45 to 3.1 m2/L) in one application only.

Limitations: do not apply ASP if Temperature falls below 50°F

STORAGE

ASP must be stored under room temperature. Shelf life is minimum two years in its original unopened packaging.

SAFETY

As with all construction chemical products, adequate precautions and care must be taken during usage and storage. Avoid direct contact with foodstuff, eyes, skin, and mouth. Any contacted areas should be washed thoroughly with clean running water and soap.

Always wear protective goggles and gloves. In case of eye contact, flush for fifteen minutes with warm water. If eye irritation persists, seek medical attention. In case of ingestion or swallowing, drink 2 glasses of clean water and seek medical attention. KEEP OUT OF REACH OF CHILDREN.

WARRANTY

LIMITED WARRANTY: International Chem-Crete warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only, and to the best of our knowledge, is accurate and reliable. International Chem-Crete cannot, under any circumstances, make any guarantee of results or assume any obligation or liability in connection with the use of this information. As International Chem-Crete has no control over product usage, it is recommended that the product be tested to determine suitability for a specific application and/or that our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner for the design, application and proper installation of each product. Specifier and user shall determine the suitability of products for specific application and assume all responsibilities in connection therewith. Any liability is limited to the replacement of material if proven faulty. AM290923-3

GALLARY

Airport Runway Application – Saudi Arabia

Bridge Application – Turkey

Parking Lot Application – Turkey