USES

CEM530 is extensively used for the grouting of tile joint widths from 2 mm up to 12 mm. CEM530 is used to fill the floor tile joints of ceramic tiles, absorptive and non-absorptive tiles, terrazzo, quarry tiles, mosaic tiles, etc.

CEM530 may be used with confidence in high traffic conditions such as:

- Factories and industrial applications

- Shopping mall and public utility services

- Industrial kitchens, dining halls and catering facilities

- Power plants and sub-stations

- Showers, toilets and bathrooms

- Decorative showrooms and domestic housing applications

- Hospitals and waiting rooms

- Swimming pools and fountains.

CEM530 may be mixed with EB550 SBR to improve color uniformity, intensity, toughness and freeze thaw durability.

TECHNICAL

Standards: CEM530 conforms to

ANSI A118.1

ANSI A108.5

Physical Properties @ 25°C

| Shear Strength 7 days, Psi (MPa), ANSI 118.1 |

320 (2.2) |

| Adhesion Strength, Psi (MPa), ASTM D-4541- Method A |

150 (1.03) |

| Open time, hour |

4 |

| Initial set, hour |

5 |

| Final set, hour |

5.8 |

| Adjustability, minute |

50 |

| Mixed density, Lb/Gal (Kg/Liter) |

15 (1.80) |

APPLICATION

Limitations:

- Do not grout if temperatures are expected to fall below 12°C within 48 hours after application.

- Grouting may be performed after 48 hours from setting installation.

- CEM530 should not be used in areas subjected to severe exposure to strong acids.

Preparation: joints to be grouted must be clean and excess mortar in the joint must be removed. The depth of each joint must be uniform to achieve consistent color intensity. The area to be grouted must be protected from varying amounts of sun, wind and heat in order to maintain consistent color.

For unglazed tiles, dampen the surface prior to grouting, but do not leave water in the joint spaces.

Mixing:

Gauging Liquid: EB550 SBR

- Use 1.5 gal (5.7L) of water to the bag of CEM530.

- Add CEM 530 to the gauging liquid of EB550 SBR and mix to a thick trowelable consistency. Avoid adding too much mixing liquid, which may cause color inconsistencies. To obtain uniform color, be consistent in the amounts of mixing liquid used. Mix at a low speed to avoid entraining excess air into the material. CEM530 can be mixed with water only. Mix to a buttery consistency.

- Let the mixed material slake for 10 minutes and remix prior to use.

Note: Do not add additional water to re-temper material.

Application:

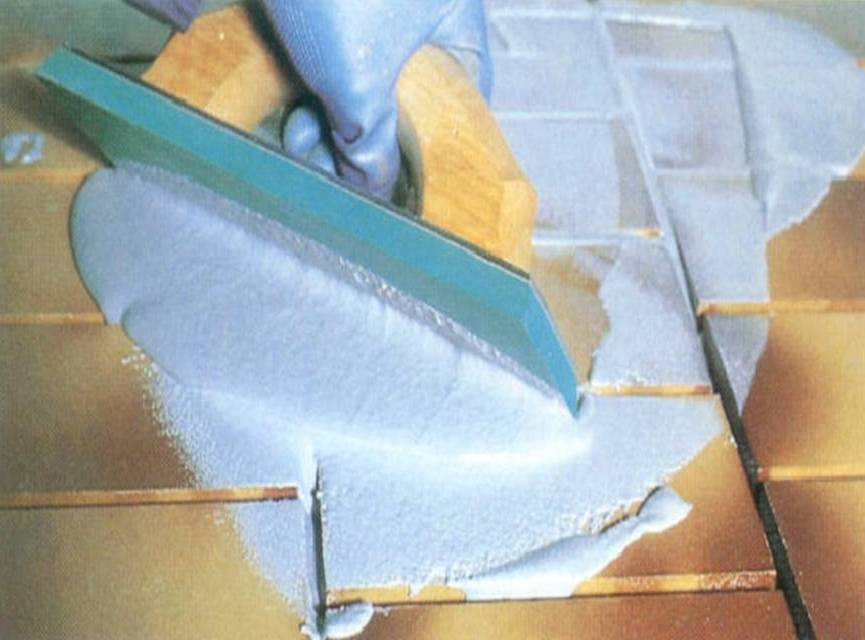

- Using an appropriate grouting float, diagonally press material into spaces with pressure to insure complete filling of the joint. Remove excess material with edge of the float.

- Once the grout has acquired an initial set, smooth the joints and remove the grout haze from the tile with a slightly dampened soft cloth. Protect grout surface with building paper for several days after installation to protect the grout from dirt, dust or stains.

- To inhibit shrinkage, cracking and color inconsistencies during dry or hot conditions, it is especially important to cover the grout joints with building paper in order to maintain a damp cure. If necessary, a final cleaning may be performed with soap and water to remove any residual grout haze from the tile surface.

A mild solution of grout cleaner, such as CONCLEAN CCC 060, suitable for tile installations, may also be used to remove well-adhered grout haze from tile. Always apply a test sample in the hidden area to evaluate performance of grout cleaner prior to entire application.

Cleaning: CEM530 should be removed and cleaned from equipment and tools with water immediately after use.

STORAGE

Store out of direct sunlight. Store in cool, dry storage facilities. Shelf life up to 12 months when stored in original bags in cool, dry storage places.

SAFETY

CEM530 is non-flammable and non-toxic in nature, avoid contact with eyes and skin as it may cause irritation due to its alkaline nature. Splashes of CEM530 should be washed off immediately with clean water. Wear necessary gloves and dust mask.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM18419.