FEATURES

- High vapor & moisture blocking performance

- Seals voids, capillaries and cracks in concrete up to 1/16th inch

- Single-component, ready-to-use and easily applied

- Low viscosity and deep penetration

- No VOC, environmentally-safe, non-toxic and odorless

- Interior/exterior, positive or negative applications

- Reduces permeability (CRD-C48-92, IDOT C4 Mix)

| Product |

Age, days |

Coefficient of Permeability, cm/se |

| SOFIX CCC 700 |

28

|

4.164 x 10-10

|

| Control (baseline) |

28

|

6.335 x 10-7

|

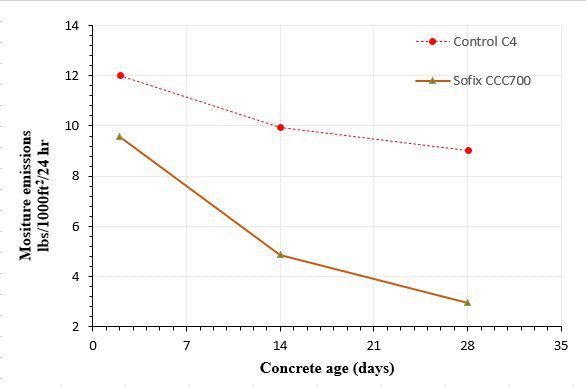

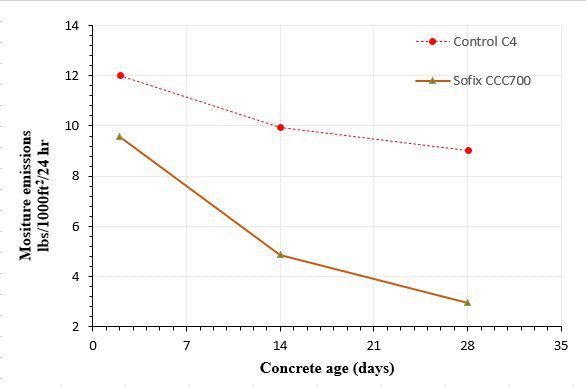

- Reduces vapor and moisture emission by up to 67% (ASTM F-2659)

Figure: ASTM F-2659 Standard Guide for Preliminary Evaluation of Comparative Moisture Condition of Concrete, Gypsum Cement and Other Floor Slabs and Screeds Using a Non-Destructive Electronic Moisture Meter

- Increases the service life of concrete coatings (protects against debonding, blistering, bubbling and adhesion failures)

- Increases the service life of concrete paints, stains and sealers

- Increases adhesion of coatings, paints and sealers

- Reduces or prevents fungus, mold, mildew, algae and bacteria growth on concrete floors, walls and under floor coverings (carpet, wood, vinyl, etc.)

- Becomes an integral part of the treated substrate

- Reduces freeze-thaw damage

- Reduces or eliminates silicate dusting

- UV stable

- Can be applied to fresh or existing concrete

APPLICATION

Methods of Application: Spray, roll or brush.

Apply using:

| – Low-pressure sprayer |

– Paint brush or roller |

| – Bristle broom |

– Squeegee |

Surface Preparation: Surface must be clean, free of surface efflorescence, paint, sealer, oil, adhesive, curing compound, form release agent and/or anything that will impede SOFIX CCC 700 penetration into the substrate.

Recommended cleaning methods include compressed air, pressure washing, scrubbing or other methods to remove surface dust, dirt or other contaminants.

Heavily contaminated areas must be cleaned using biodegradable concrete cleaners (CHEM-CRETE CONCLEAN CCC060, recommended) and a pressure washer to remove deeply penetrating contaminants.

SOFIX CCC 700 may be applied to damp surfaces free from standing water.

If installing resilient flooring, follow ASTM F710 (Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring)

Coverage: Two coats required, 200 ft2 per gallon, per coat (4.91 m2 per liter, per coat). Excessively porous substrates may require additional material. Apply with an even, uniform spreading rate.

Limitations: Do not apply under the following conditions:

- Temperature below 40ºF (5°C)

Precautions: During application, do not allow product to come in contact with metal or glass. If contact occurs, immediately wash contacted area with water to prevent crystal formation.

Cleaning: Clean all equipment and tools with clean water immediately after use.

STORAGE

Two-year shelf life when stored in its original, unopened container, in a cool, dry place. Always agitate the product before using. DO NOT ALLOW PRODUCT TO FREEZE. Repeated freezing and thawing may cause damage to the product.

SAFETY

As with all construction chemical products, adequate precautions and care must be taken during usage and storage. Avoid direct contact with foodstuff, eyes, skin and mouth. Contacted areas should be washed thoroughly with clean running water and soap.

Always wear protective goggles and gloves. In case of eye contact, flush for fifteen minutes with warm water. If eye irritation persists, seek medical attention. In case of ingestion or swallowing, drink two glasses of clean water and seek medical attention. KEEP OUT OF REACH OF CHILDREN.