USES

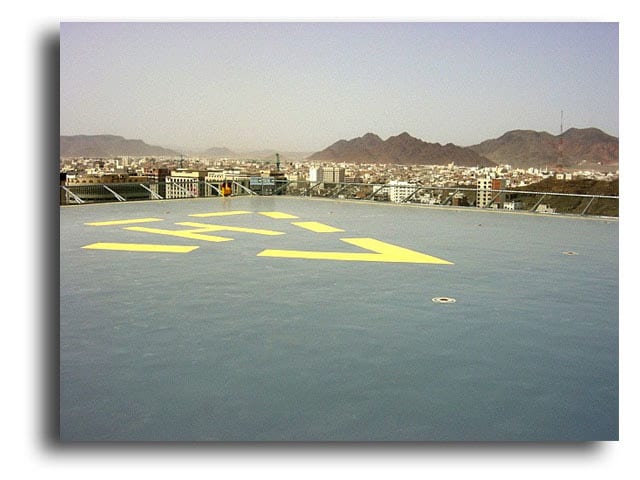

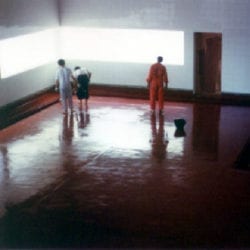

Abrasion and chemical resistant, heavy-duty coating for use on floors in maintenance areas, generator rooms, aircraft hangars, workshops, warehouses, computer rooms, car parking, factory floors, and hospitals. A practical and decorative coating system, for application on concrete, steel, galvanized metal, masonry and wood.

TECHNICAL

Properties for uncured Parts:

| Property @ 25°C (77°F) |

Part A – Resin

|

Part B – Hardener

|

Test Method

|

| Solids by weight, % |

81 |

73 |

–

|

| Color |

Grey |

Amber |

–

|

| Density, Lb/Gal (Kg/L) |

12.2 (1.46) |

7.9 (0.95) |

ASTM D1475 |

| Shelf Life |

2 years |

2 years |

–

|

Properties for cured Parts:

| Property |

Value @ 25°C

|

ASTM Method

|

| Mixed Density, Lb /Gal (Kg /Liter) |

11.5 (1.38) |

D-1475 |

| Gel Time @ 60 grams, minute |

360 |

D-2471 |

| Pot Life @ 5 kg, minute |

210 |

–

|

| Hardness (Shore) |

30 D, 78A |

D-2240 |

| Bond Strength to concrete |

Concrete Failure |

D-4541 Method C |

| Bond Strength to steel, Psi (MPa) |

11.3 (1.36) |

C-321 |

| Water Absorption |

0.24 % |

D-570 |

| Recoat Interval, hour |

6 to 72* |

–

|

| Solid Content by weight, % |

80 |

–

|

| Final Cure, day |

10 |

–

|

* depending on temperature

Chemical Resistance: tests are performed according the ASTM D543 –Practice A (Immersion test for 7 days at 25°C). The fully cured CHEM-GUARD 80 coating is resistant to:

- Water (Distilled, Tap, chlorinated, sewage, sea)

- Economical

- Sulfuric acid 70%wt*

- Sulfuric Acid 50%wt

- Citric Acid 30%wt

- Isopropanol

- Xylene

- Acetic Acid, 10% wt

- Caustic Soda, 30%

- Hydrochloric Acid, 38%

- Diesel

- Diesel Engine Oil

- Hydraulic Oil

* Small Surface Blisters.

Refer to manufacturer for resistance of other reagents.

APPLICATION

Limitations: Application at ambient temperature below approximately 41°F (5°C) is not recommended. Exposure to temperatures exceeding 65°C for prolonged periods is not recommended.

Surface Preparation:

Concrete Substrate: As with all coatings it is imperative that proper surface preparation is achieved. Allow new concrete to cure, prepare by sandblasting or grinding. Surfaces should be sound or taken back to a sound base then reinstated where necessary. All grease, curing compounds, laitance or other deleterious matter should be removed.

Steel Surfaces: Minimum requirements of commercial sandblasting to SA 2½.

Galvanized Metal: Roughen up surface and degrease using solvents, ensure adhesion by testing.

Wood Surfaces: Sand smooth and remove contaminants.

Mixing: component B should be added to component A ensuring they are completely mixed. Mixing can be manual or by slow speed drill and mixing paddle.

Application: after thoroughly mixing the product, apply by either brush, roller, or airless spray equipment. Apply the first coat ensuring no pinholes are visible. The second coat should be applied after 6 hours at 77°F (25°C). Anti slip finish can be obtained by sprinkling silica aggregate 0.1-0.3 mm grain size into the first coat. Ensure that any loose aggregate is removed prior to the application of the second coat.

Cleaning: Remove uncured CHEM-GUARD 80 from tools and equipment with suitable solvents such as Xylene, Toluene or CHEM-CRETE BLENDED SOLVENT immediately after use. Cured material may only be removed mechanically.

STORAGE

At least one year in unopened cans. Containers should be stored in air-conditioned facilities.

SAFETY

Keep resin and hardener away from eyes and skin contact. Good ventilation should be provided particularly in closed work areas.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, t0 the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM22319.