USES

CHEM-VOID is mainly used for repairs and sealing of various types of concrete wider cracks which are dormant without any movements, filling cavities, honeycombs, segregated concrete, etc. CHEM-VOID can also be used as grout for fixing anchor bars, bolts in horizontal applications.

TECHNICAL

Technical Data for Unmixed Parts

| Property @ 25°C (77°F) |

Resin – Part A |

Hardener – Part B |

Test Method |

| Solids |

100 % |

100 % |

–

|

| Color |

Grey |

Clear |

–

|

| Density, Lb/Gal (Kg/L) |

< 14.89 (1.78) |

< 7.90 (0.95) |

ASTM D-1475 |

| Mixing Ratio A: B |

2: 1 By Volume

|

–

|

| Shelf Life |

2 years |

2 years |

–

|

Technical Data for Mixed Parts – 2A:1B

| Property (Mixed A & B) |

Value @ 25°C (77°C) |

Test Method |

| Mixed Density, Lb/Gal (kg/L) |

12.56 (1.52) |

ASTM D1475 |

| Mixed Viscosity cP (kPa.s) |

1700 (1.7) |

Brookfield |

| Pot Life @ 3 oz. (90 milliliter), hour |

4 |

–

|

| Pot Life @ 1.5 Gal (5.68 Liter), minute |

1 |

–

|

| Shore Hardness @ 3 Days, D |

85-D |

ASTM D2240 |

| Compressive Strength @ 7 Days, Psi (MPa) |

16000 (110) |

ASTM D695 |

| Elongation, % |

6 |

D-638 |

| Water Absorption 24 hrs, % |

< 0.23 |

ASTM D570 |

APPLICATION

Limitations:

| Minimum substrate temperature |

+ 5°C |

| Maximum permissible moisture content of substrate |

5 % |

| Minimum temperature for mixing and application |

+ 5°C |

Pre-treatment of Substrate: the substrate must be sound, dry, clean, and free from oil, grease, etc. All loose material and laitance should be removed by mechanical means. Steel should be shot blasted to bright metal.

Mixing Ratio: Component ‘A’: Component ‘B’ = 2: 1 parts by volume.

Select a suitable dry, clean container for mixing. Pour both components ‘A’ and ‘B’ completely and mix thoroughly using a low speed electric drill with mixing paddle. Mix from side to side and top to bottom until a fully homogenous mixture is obtained.

Mixing Time: approximately 3-5 minutes Mix only quantities, which can be processed within the pot life.

Pot Life: the prepared mix should be used up immediately at least within 40 minutes at 25°C.

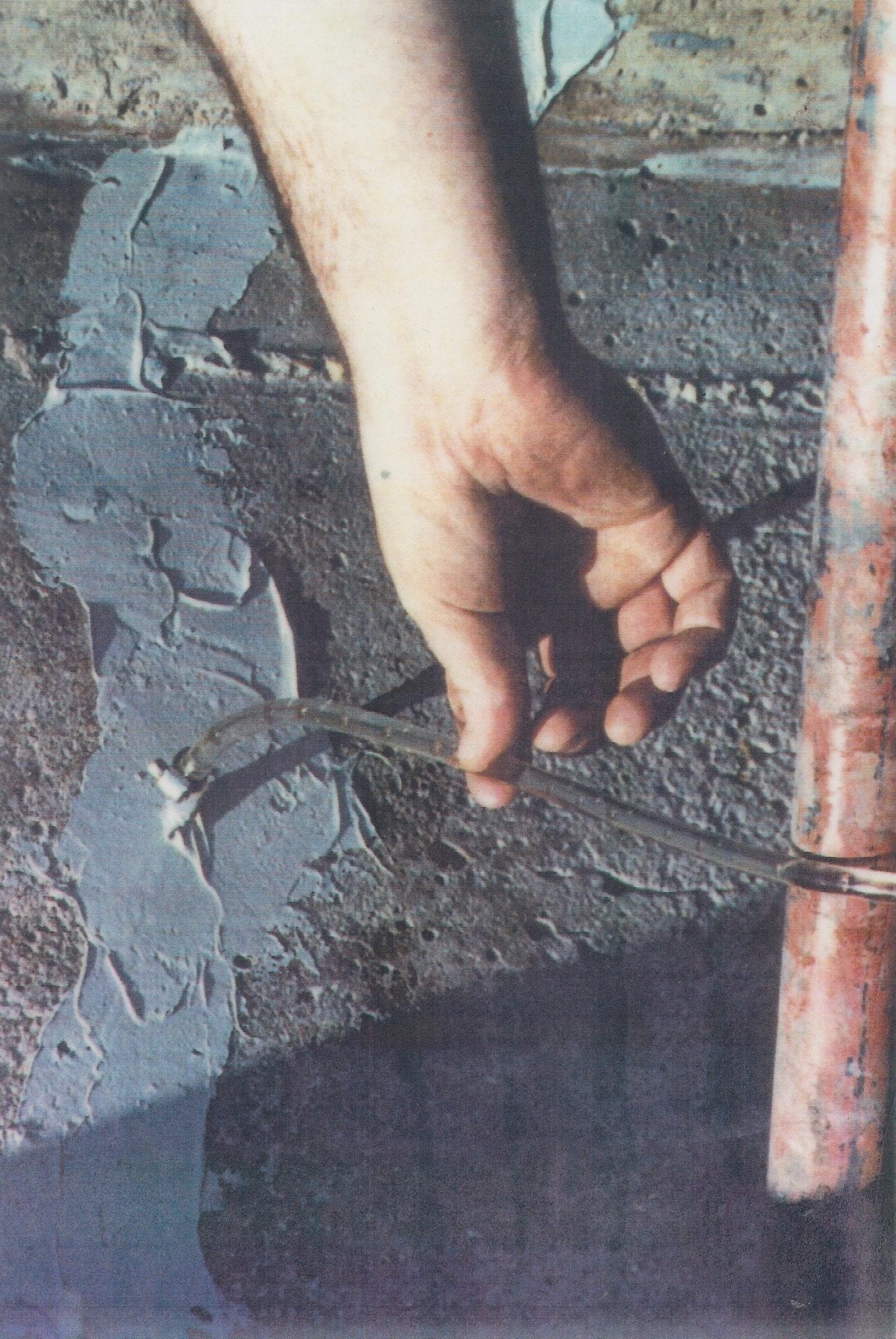

Injection: inject CHEM-VOID through the injection packers after the wide cracks have been sealed. Allow Chem-Void to cure for 48 hours before packers and Crack Sealing Compound is removed.

Curing: observe standard curing practice for the newly placed concrete or hydraulic mortars.

Cleaning: tools and equipment contaminated with Chem-Void should be cleaned up immediately with Blended solvents.

STORAGE

The product can be stored in a dry cool place for one year in unopened original packaging. Do not store below +10°C or in direct sunlight. Prior to the application of Chem-Void it should be maintained at approximately 25°C for at least 24 hours, in order to have consistent workability, curing and better finishing.

SAFETY

After full cure, CHEM-VOID is physiologically harmless. Keep the resin and hardener away from the eyes mouth and skin. Do not breathe in the vapors. The uncured mixture can cause irritation of the skin. For best protection, wear rubber or plastic gloves. In case of contamination, wipe away resin or hardener immediately from the skin using paper towels and then wash with soap and water or hand cleaning detergent. Empty resin and hardener cans must be destroyed. Under no circumstances use them to store food or drink even if they have been thoroughly cleaned.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM22319.