USES

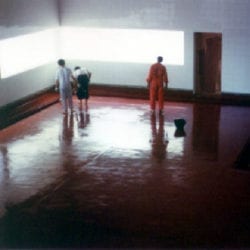

CHEM-FLOOR can be used for industrial and commercial applications like:

- Chemical processing Plants

- Food processing Plants and Slaughterhouses

- Laboratories

- Pharmaceutical plants

- Power plants, switchgear rooms, turbine areas

- Bottling plants

- Restaurants

- Hospitals

- Nursing Homes

- Schools

- Offices and corridors

- Washrooms

- Commercial kitchens

TECHNICAL

Technical Data for Unmixed Parts

| Property @ 25°C (77°F) |

Resin Part A |

Hardener Part B |

Test Method |

| Solids |

100 % |

100 % |

–

|

| Color* |

Clear or Grey* |

Clear |

–

|

| Density (Clear), Lb/Gal (Kg/L) |

< 9.53 (1.142) |

< 8.03 (0.962) |

ASTM D1475 |

| Density (Grey), Lb/Gal (kg/L) |

< 11.01 (1.320) |

< 8.03 (0.962) |

ASTM D1475 |

| Viscosity (Clear), cP |

2370 |

20 |

Brookfield |

| Viscosity (Clear), cP |

6050 |

20 |

Brookfield |

| Mixing Ratio A : B |

3 : 1 By Volume |

–

|

| Shelf Life |

2 years |

2 years |

– |

* Refer to epoxy coatings and floorings color chart for standard colors. More colors are available for CHEM-FLOOR product. Custom colors are available upon request. Contact International Chem-Crete for more information.

Technical Data for Mixed Parts

| Property (Mixed A & B) |

Value @ 25°C (77°C) |

Test Method |

| Mixed Density Clear, Lb/Gal (kg/L) |

< 9.15 (1.097) |

ASTM D1475 |

| Mixed Viscosity (Clear), cP |

460 |

Brookfield |

| Mixed Density Grey, Lb/Gal (kg/L) |

< 10.35 (1.24) |

ASTM D1475 |

| Mixed Viscosity (Grey), cP |

760 |

Brookfield |

| Gel Time @ 60 grams, minute |

95 |

ASTM D2471 |

| Pot Life @ 1 Quart (1 Liter), minute |

45 |

–

|

| Shore Hardness @ 3 Days, D |

80 |

ASTM D2240 |

| Compressive Strength @ 7 Days, Psi (MPa) |

11487 (79.2) |

ASTM D695 |

| Bond Strength to concrete |

Concrete Failure |

ASTM D4541, Method C |

| Water Absorption 24 hrs, % |

< 0.15 |

ASTM D570 |

| Elongation (Average), % |

18.5 |

ASTM D522, Method A |

| Abrasion Resistance (CS-10 Wheels/1000 grams load / 1000 cycles), mg loss |

50 |

ASTM D4060 |

| Maximum Recoat Interval, hour |

24 – 36 |

–

|

| Final Cure, day |

7 |

–

|

Chemical Resistance: Tests are performed according to ASTM D543 – Practice A (Immersion test for 7 days at 77°F/25°C). The fully cured product is resistant to:

- Water (Distilled, Tap, chlorinated, sewage, sea)

- Sulfuric Acid 50%*

- Citric Acid 30%

- Caustic Soda 50%

- Hydrochloric acid 15%

- Diesel

- Hydraulic Oil

* Minor Color Change

Refer to manufacturer for resistance of other reagents.

APPLICATION

Limitations: Application at ambient temperature below approximately 41°F (5°C) is not recommended. Exposure to temperatures exceeding 149°F (65°C) for prolonged periods is not recommended. Substrate temperature must not be lower than 41°F (5°C) during installation and during the full 3 to 5-day cure of the floor

Coverage: 1 Gallon of CHEM-FLOOR will yield 20 mils (500 microns) when applied at 80 ft2 / Gallon (1.96 m2 / Liter).

Surface Preparation:

Concrete Substrate: Surface of application should be clean and sound. The surface must be free of any dust, oil, grease, laitance, curing compounds or any other contaminants. New concrete substrate should be 28 days old and must be a minimum of 3625 Psi (25 N/mm2) compressive strength concrete. Chlorinated rubber, wax or resin based curing compounds must not be used. CHEM-FLOOR should not be applied on surfaces that have been sealed with a permanent type of form oil, releasing agents, etc. Remove these substances before application of CHEM-FLOOR. The surface temperature shouldn’t be below 41°F (5°C).

Acid Etching: On new concrete surfaces, remove laitance and un-bonded cement particles by acid etching. Dampen the surface with tap water. Use Chem-Crete’s CONCLEAN CCC070 or dilutes Muriatic acid to a 10% solution. Always add the acid to the water. Scrub the acid water solution onto the surface at the rate of 50 ft2 / Gal (1.22 m2 / liter). Allow the solution to sit for 20 minutes or until the acid bubbling stops. Scrub and flush thoroughly with clean water until all traces of acidity are washed-off from the surfaces. Remove water by squeegee, vacuum or broom and allow the surface to air dry. Other methods may be adopted if the acid etching method is not feasible, such as shot blasting, sand blasting or mechanical grinding.

Product Preparation: Store product at 70°F (21°C) during application and for at least 2 days prior to use. Low temperature will increase the viscosity of the product causing poor coverage and retarded cure.

Use of Water Moisture and Vapor Blocker: Water moisture transmission through concrete floors where CHEM-FLOOR will be applied should be less than 5 Lbs per 1000 ft2 per 24 Hours based on ASTM F1869 (Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride). In case moisture emission rate equals or greater than 5 Lbs per 1000 ft2 per 24 Hours, moisture blockers like CHEM-CRETE SOFIX CCC100 and CHEM-CRETE SOFIX CCC700 should be sued, refer to these products’ data sheets for more information about how to use these products. The use of these moisture blockers will extend the service life of the coating by eliminating moisture and vapor associated problems like; coating degradation, coating de-bonding and blistering.

Mixing: CHEM-FLOOR is supplied it two pre-weighed parts resin and hardener. No additions or omissions are required. Stir each part separately. Pour part B (hardener) into the container of part A (resin). Mix both parts using slow speed hand drill fitted with a mixing paddle attachment. Carefully scrape the sides and bottom of the pail during mixing. Blend for 3 minutes until achieving a uniform color and consistency. Mixed epoxy must be processed within the pot life. Mixed epoxy will cure much faster in hot weather. Large batches of mixed epoxy will cure much faster than small batches. Always keep the mixing time the same for all batches to ensure a uniform consistency when the product is applied.

Application:

Method 1 – As a clear sealer for heavy duty epoxy mortar screed surfaces:

- Apply the mixed CHEM-FLOOR by roller or brush at an average coverage of 200 ft2 / Gal (5 m2 / liter).

- Within 24 hours, apply the second coat by brush or roller at approximate coverage of 200 ft2 / Gal (5 m2 / liter). Take care to remove all excess resin with a rubber squeegee. With the application of two coats of CHEM-FLOOR sealer, the slightly porous epoxy mortar screed will be sealed completely.

Method 2 – As a floor coating:

- Apply the mixed material by brush or roller at an average coverage of 200 ft2 / Gal (5 m2 / liter). Pour the mixed material and pull out to the desired thickness using a notched squeegee and back roll. Use a spiked roller to remove any trapped air from the coating. Wear spiked shoes to avoid slipping or damaging the system. A minimum of two coats is required.

- Apply the second coat at an average coverage of 200 ft2 / Gal (5 m2 / liter) and after the first coat is tack-free, but within 24 hours. If the first coat cures longer than 36 hours, the surface must be roughened up by light brush grinding or with sandpaper.

Method 3 – As Non-slip Aggregate Flooring System:

- Surfaces that are damp, porous or have a rough concrete finish should be primed with CHEM-FLOOR Clear or CHEM-PRIME at an average coverage of 200 ft2 / Gal (5 m2 / liter).

- Apply the CHEM-FLOOR Clear base coat at an average coverage of 100 ft2 / Gal (2.5 m2 / liter) with a squeegee and then back roll with a short napped mohair roller with a solvent resistant core. Let the epoxy level out on the substrate for 5 minutes.

- While the epoxy resin coat is still wet, the color blend of aggregate or silica sand 0.3-0.8 mm grade is sprinkled onto it by hand or by any suitable broadcasting method. Excess of aggregate must be used to facilitate a good coverage of the substrate, otherwise, sparse areas or voids will be formed which will require an additional coat of aggregate. If a wet or glossy appearance on aggregate is evident, it is an indication that insufficient aggregate has been applied. Use of spiked shoes by the applicator is advised while broadcasting the aggregate. CHEM-FLOOR Clear base coat with aggregate must be allowed to dry before proceeding with the next step. Always leave a wet edge of about one-foot without ridges to allow for joining the next course of material.

- Remove all loose aggregate of sand by either sweeping or preferably vacuum cleaning. Sand-off any imperfections using a floor sander. Sweep and vacuum debris prior to applying the second broadcast. Apply an additional Base coat and aggregate as described above.

- The finish coat of CHEM-FLOOR is applied to the surface at a rate of 100 ft2 / Gal (2.5 m2 / liter) with a squeegee. Draw down the finish coat until the desired surface texture is obtained and back roll with a short nap mohair roller with a phenolic core to smooth out the applied coating.

Cleaning: remove uncured CHEM-FLOOR from tools and equipment with suitable solvents such as Xylene, Toluene or CHEM-CRETE BLENDED SOLVENT immediately after use. Cured material may only be removed mechanically.

STORAGE

The product can be stored for minimum of twelve months at temperature from 50°F to 95°F (10°C to 35°C) in the unopened original packaging. Protect from direct sunlight.

SAFETY

After hardening thoroughly, CHEM-FLOOR is physiologically harmless. Keep the resin and hardener away from the eyes mouth and skin. Do not breathe in the vapors. The uncured mixture can cause irritation of the skin. For best protection, wear rubber or plastic gloves. In case of contamination, wipe away resin or hardener immediately from the skin using paper towels and then wash with soap and water or hand cleaning detergent. Empty resin and hardener cans must be disposed according to local city code or regulations. Under no circumstances empty cans should be used to store food or drink even if they have been thoroughly cleaned. Follow all cautionary direction as printed on container’s labels.

WARRANTY

LIMITED WARRANTY: International Chem-Crete Inc. warrants that, at the time and place we make shipment, our materials will be of good quality and will conform to our published specifications in force on the date of acceptance of the order.

DISCLAIMER: The information contained herein is included for illustrative purposes only and, to the best of our knowledge, is accurate and reliable. International Chem-Crete Inc. is not under any circumstances liable to connection with the use of information. As International Chem-Crete Inc. has no control over the use to which others may put its products, it is recommended that the products be tested to determine the suitability for specific applications and/or our information is valid in particular circumstances. Responsibility remains with the architect or engineer, contractor and owner of the design, application and proper installation of each product. Specifier and user shall determine the suitability of the product for specific application and assume all responsibility in connection therewith. AM250311